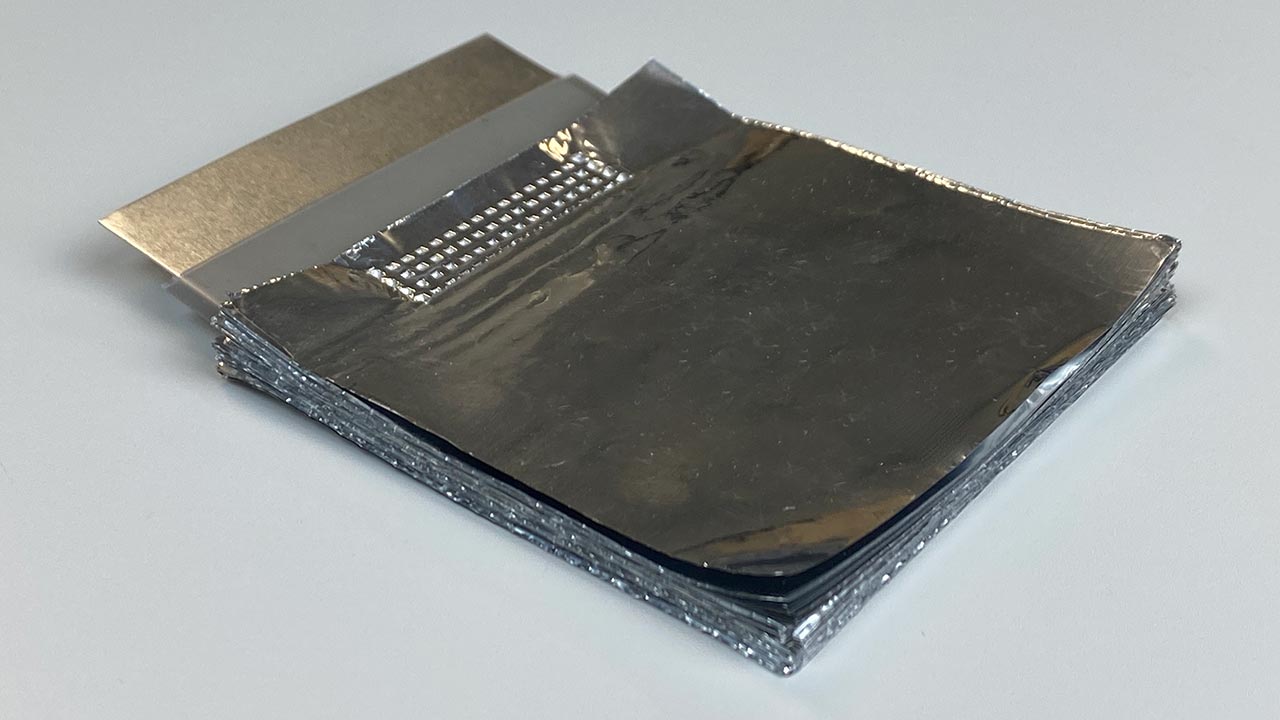

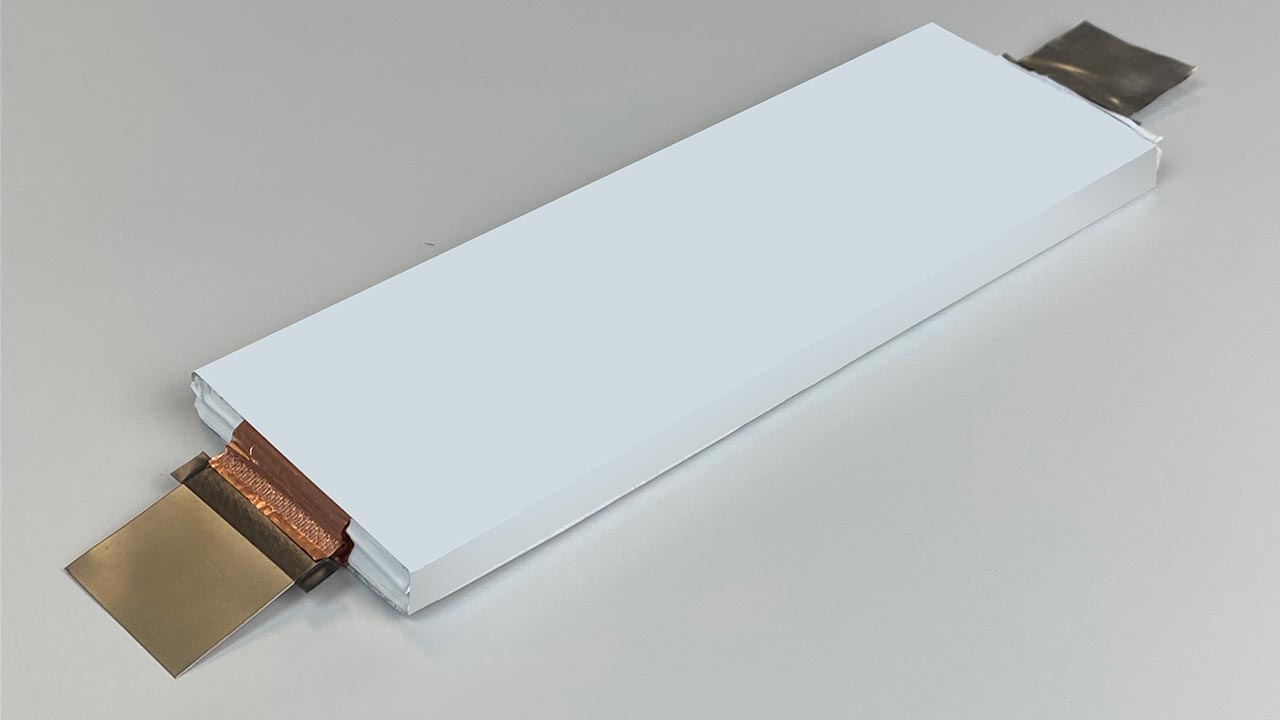

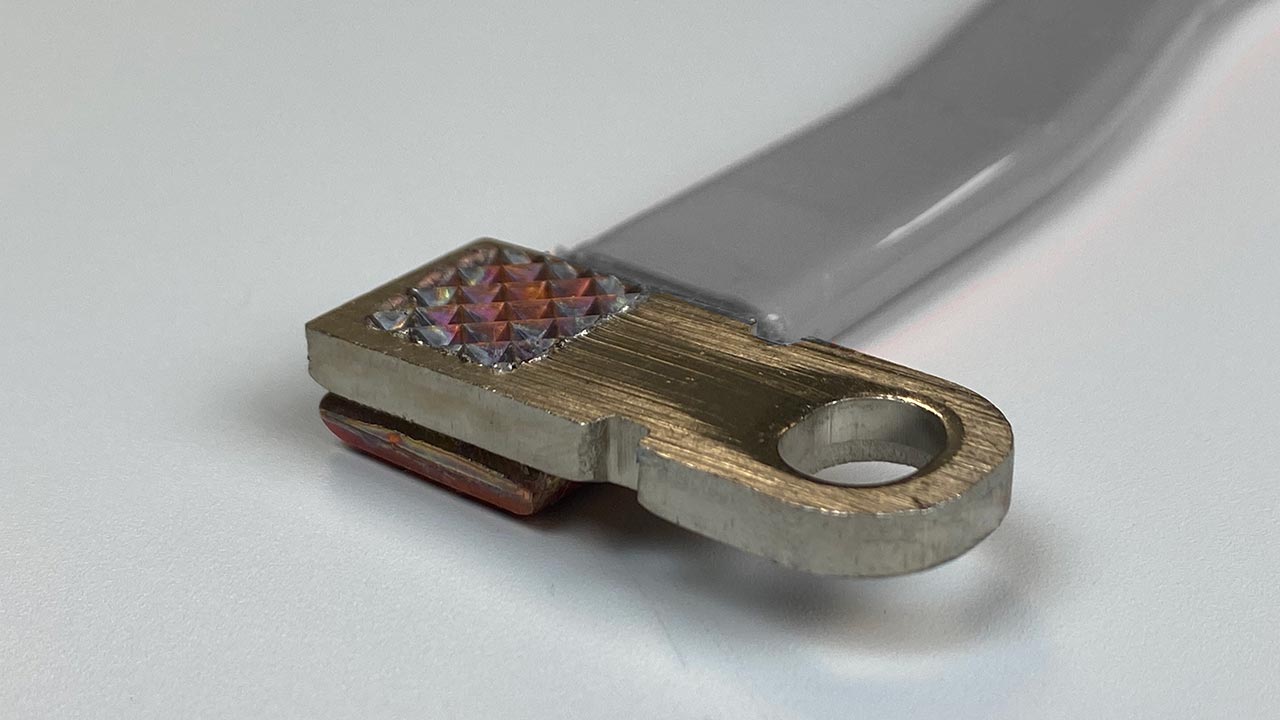

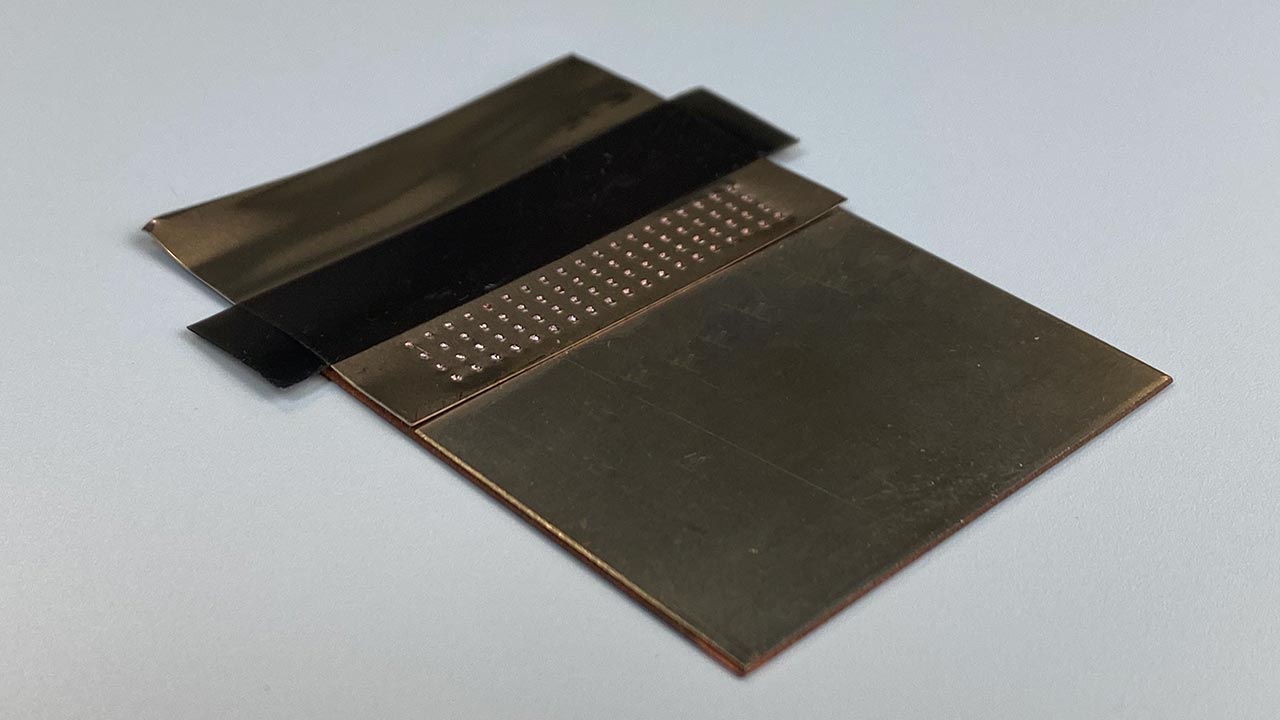

EV Battery Samples and Products

TECH-SONIC is the first manufacturer to develop a highly-advanced servo-controlled ultrasonic metal welding process, known as Closed-Loop Control Ultrasonic Welding. This technology is particularly useful in spot welders for EV battery assembly. It combines the latest technologies in ultrasonic welding, servo control, user-friendly microprocessor control, and load cell force feedback, providing a 100% digital welding process.

Having been involved in lithium battery welding since 1996, TECH-SONIC has been working with many of the leading EV battery manufacturers of the world over twenty years of operation. With long established expertise in lithium battery welding, TECH-SONIC has been working with these manufacturers on new advanced solutions in welding foil stacks, foil-to-tab, foil-to-busbar, and tab-to-busbar to meet the needs of assembling current and future batteries. With experience in welding materials ranging from aluminum, copper and other non ferrous metals.

US-935S

US-3620S

US-3620SH

US-5020SH